Introduction

The Winkelbohrspindel, also known as an angle drilling spindle, has become an essential component in modern manufacturing environments where precision, accessibility, and productivity matter. Early in any machining process, technicians often encounter challenges—tight corners, inaccessible angles, or delicate materials that require controlled drilling. This is exactly where the Winkelbohrspindel proves its value. Designed to reach difficult spots while maintaining exceptional accuracy, this tool has transformed production across industries including automotive, aerospace, woodworking, and metal fabrication. By enabling operators to drill precisely at non-standard angles, it reduces downtime, improves workflow, and ensures consistency across repetitive tasks.

In the past, manufacturers relied on improvised setups and unstable attachments to reach angled positions. These solutions often produced inconsistent holes and created safety risks. Today’s Winkelbohrspindel models offer carefully engineered components, controlled torque transmission, and modular attachments that guarantee stable, repeatable performance. Because industries demand more complex shapes and compact assemblies, the importance of angle drilling technology continues to grow. The Winkelbohrspindel not only supports efficiency but also empowers companies to expand production capabilities without costly machinery replacement. When integrated into a CNC setup or used with handheld tools, the Winkelbohrspindel becomes a versatile solution suited for both small workshops and advanced manufacturing plants.

How a Winkelbohrspindel Works

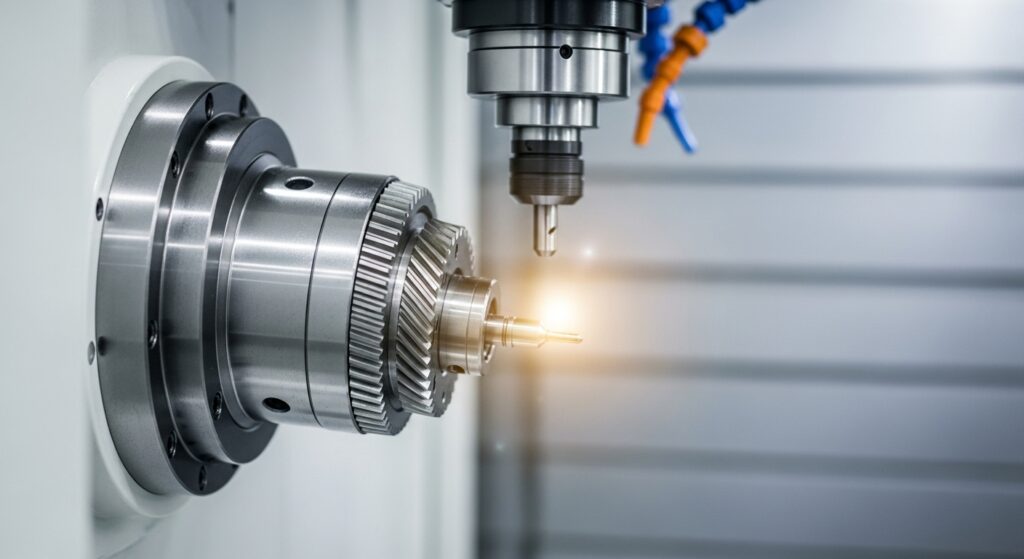

The Winkelbohrspindel operates by transferring rotational force through a 90-degree mechanism, typically using bevel gears or high-strength angular bearings. This internal arrangement ensures the spindle maintains consistent torque even when drilling at awkward angles. By stabilizing the bit during rotation, the device reduces wobble and maintains drilling accuracy. Advanced models also include lubrication channels to minimize friction and extend component life. With a well-designed Winkelbohrspindel, operators can rely on smoother drilling performance and cleaner hole patterns, especially in dense materials such as steel or carbon composites.

Another key aspect of how the Winkelbohrspindel functions is its compatibility with various tool holders, machine interfaces, and RPM ranges. Manufacturers often design their spindles to fit seamlessly into CNC systems or robotic arms. This versatility makes the tool especially valuable in high-precision settings such as aerospace assembly lines, where millimeter-level accuracy is essential. Whether used for drilling, countersinking, or reaming, the Winkelbohrspindel allows operators to maintain tight tolerances without repositioning entire workpieces.

Read More: Food Trends FHTHopeFood

Industrial Applications of the Winkelbohrspindel

The Winkelbohrspindel plays a vital role in industries that work with large assemblies where straight-on drilling is impossible. In automotive manufacturing, technicians frequently need to drill inside chassis structures or narrow engine compartments. The angle spindle enables clean, consistent holes without requiring disassembly of major components. This boosts productivity and reduces labor hours. Its high torque capacity also supports the machining of sturdy frame materials and reinforced panels.

Aerospace and aviation industries rely on the Winkelbohrspindel for precision drilling in confined spaces such as wing structures, cockpit interiors, and fuselage sections. In these cases, accuracy is non-negotiable because hole alignment affects performance, aerodynamics, and safety. Many modern aircraft designs feature curved or layered surfaces that require angled access. The Winkelbohrspindel delivers the consistency necessary to meet strict regulatory standards while minimizing material stress.

Benefits of Using a Winkelbohrspindel

One of the most important benefits of a Winkelbohrspindel is increased accessibility. Operators can reach areas that would otherwise require complete disassembly of large machinery or structures. This not only saves time but also lowers operational costs. Because the spindle operates at an angle without compromising stability, it helps maintain drilling exactness and reduces user fatigue.

Another major advantage is enhanced safety. Instead of forcing tools into positions they weren’t designed to reach, workers benefit from a specialized device that ensures proper force alignment. This reduces the risk of tool kickback, bit breakage, or material damage. Additionally, a high-quality Winkelbohrspindel contributes to better overall surface quality and reduces the likelihood of rework or rejected parts.

Key Features to Look for in a Winkelbohrspindel

When selecting a Winkelbohrspindel, durability should be a priority. Look for units with hardened gears, reinforced bearings, and corrosion-resistant housing. These features ensure long-term reliability under continuous use. Another important feature is vibration reduction, which helps deliver clean drilling results and extends tool lifespan.

Compatibility also plays a significant role. Some Winkelbohrspindel models are designed for high-speed applications, while others prioritize torque for heavy-duty drilling. Choosing a spindle that fits your machine type, task requirements, and material specifications ensures optimal performance. You may also want to consider coolant channels, tool-change systems, and ergonomic design when making your selection.

Maintenance and Longevity of the Winkelbohrspindel

Proper maintenance significantly extends the lifespan of a Winkelbohrspindel. Regular lubrication of internal gears prevents friction buildup and reduces wear. Cleaning the spindle after each use helps remove metal shavings, dust, and debris that could interfere with smooth operation. You should follow manufacturer guidelines for inspection intervals and replacement parts.

Another aspect of maintenance is monitoring operational performance. If you notice unusual vibration, reduced torque, or inconsistent drilling results, it may indicate internal component fatigue. Addressing issues early prevents expensive repairs later on. High-quality Winkelbohrspindel models are designed to withstand demanding industrial environments, but proactive care ensures they deliver consistent results year after year.

CNC Integration with a Winkelbohrspindel

Modern CNC systems frequently pair with a Winkelbohrspindel to expand machining capabilities without redesigning a workspace. With CNC control, angle drilling becomes even more precise, allowing automated drilling sequences on curved or restricted surfaces. This reduces human error and improves production speed. Many CNC manufacturers provide modular spindle attachments to ensure seamless integration.

In automated environments, a Winkelbohrspindel also supports multi-axis functionality. Robots equipped with angle spindles can machine complex components from a single position, reducing the need for manual repositioning. This increases throughput while maintaining accuracy across production runs. As automation advances, the role of the Winkelbohrspindel will continue to grow in smart manufacturing systems.

Conclusion

The Winkelbohrspindel has evolved into a powerful solution for modern precision drilling needs. Its ability to deliver accurate results in tight or angled spaces has transformed workflows across industries such as automotive, aerospace, woodworking, and metal fabrication. By reducing the need for disassembly, improving drilling stability, and enhancing safety, the Winkelbohrspindel helps manufacturers achieve higher quality standards while controlling costs. Whether you operate a small workshop or manage a large industrial facility, incorporating a reliable Winkelbohrspindel into your processes can significantly broaden your machining capabilities. As manufacturing continues to move toward automation and complex design, this tool remains a cornerstone of efficient, precise, and flexible production.